Skanpak | Jílové u Děčína

The customer has many years of experience with lasers, which allowed them to provide us with an excellent specification.

Our team handled *.ams files without any issues; these are generated by Skanpak’s own CAD software. We also work with other CAD programs for die design, such as MarbaCAD, which generates *.CFF2 files.

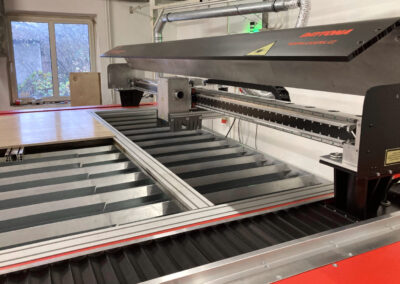

The machine for Skanpak was customized to the dimensions and properties of the semi-finished products, with consideration for easy handling.

On the new ALT laser, the customer particularly appreciates the accuracy and perpendicularity of the cut, which simplifies knife assembly. Combined with the cutting speed, this provides significantly higher productivity at lower costs.

| Work area | 2500 × 1500 mm |

| Laser power | 650 W |

| Laser type | Rofin-Luxinar CO₂ closed, wavelength 10.6 µm |

| Cutting speed | Up to 2 m/s, depending on the material |

| Processed material | Wooden boards |

| Table concept | Fixed table with sectional extraction |

| Material loading | Manual, with a mechanism to secure boards |

| Additional features | AMS file import, contour processing, propal, and automatic focusing (“autofocus”) for precise cutting |