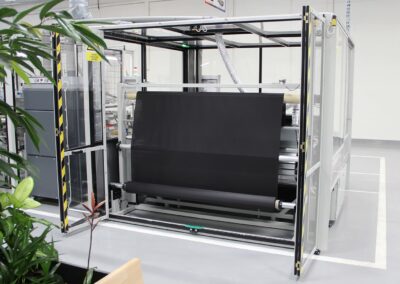

Webasto 1 | Liberec

A few years ago, a manufacturer of automotive roof systems approached us with a request to develop a technology for cutting special textiles for Mercedes vehicles.

The problem lay in the chemical composition of the material – a standard laser cut could not achieve the perfectly clean edge that Daimler Benz required without compromise.

Unlike our competitors, we found a solution and, for a certain period, cut parts for Mercedes roofs on our test lasers under quasi-laboratory conditions. At the same time, we were developing the design of a machine suitable for integration into the production line.

Precision, productivity, and reliability – essential in the automotive industry – are standard features of our lasers. We had already solved the cutting cleanliness; the next step was to optimize the machine design so it would fit perfectly into the line and ensure the simplest possible handling of semi-finished and finished products.

Eventually, we fully automated the process – added advanced diagnostics, solved product tracking and label printing, ensured file generation for recording operational history, and detected defective semi-finished products.

The operator simply loads the material, selects the vehicle type, presses a button, and production runs.

If you’ve recently bought a Mercedes with a retractable roof, a part of our work is inside it.

You can find another laser we delivered to Webasto here.

| Working area | 1800 × 1200 mm |

| Laser power | 100 W |

| Laser type | Synrad CO₂ enclosed, wavelength 10.6 µm |

| Cutting speed | Up to 2 m/s, depending on material type |

| Processed material | Technical textiles |

| Table concept | Aluminum conveyor with special anti-reflective coating |

| Material feeding | Automatic unwinder |

| Extraction and filtration unit | Filter with activated carbon |

| Additional functions | Automatic material fault detection |