Thanks to precise construction and reliable components, our laser machines deliver maximum accuracy and long service life.

Laser Source

The choice of laser type and power determines whether and how quickly a material can be processed. Our greatest experience is with Synrad and Iradion lasers from the USA, known for their long lifespan, stable output, and high reliability. That’s why our systems are primarily equipped with these lasers.

Optics

The function of the optics is to optimize the laser beam parameters, transport the beam from the laser to the cutting head, and focus it precisely on the material.

We build optical systems from components by the British company ULO, whose main advantage is long durability. The higher initial cost quickly pays off by eliminating expenses and downtime associated with frequent lens or mirror replacement. With proper care, these components last for many years.

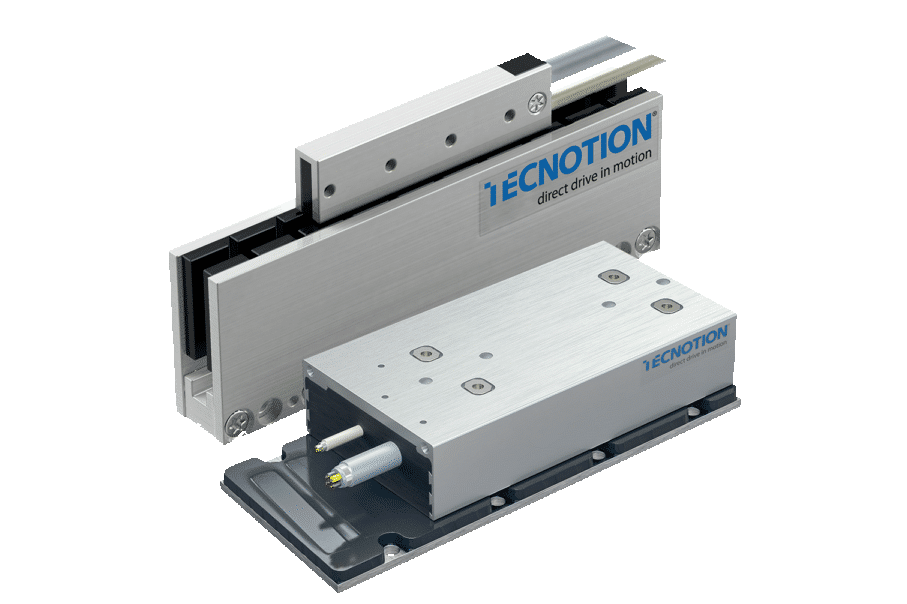

Mechanics

The machine’s mechanics control the movement of the cutting head according to the cutting plan. The speed and rigidity of the construction significantly affect edge quality and overall cutting accuracy.

We use a combination of welded structures and composite materials.

Maximum dynamics and precision are ensured by linear motors from the Dutch company Technotion, complemented by linear guides and an integrated measurement system from the Swiss company Schneeberger.

Measurement

The measurement system reports the cutting head’s exact position to the control system and determines cutting accuracy. It allows real-time monitoring and correction of the laser movement, minimizing errors in complex cuts and ensuring repeatability. The system also enables automatic compensation for deviations caused by temperature changes or mechanical wear.

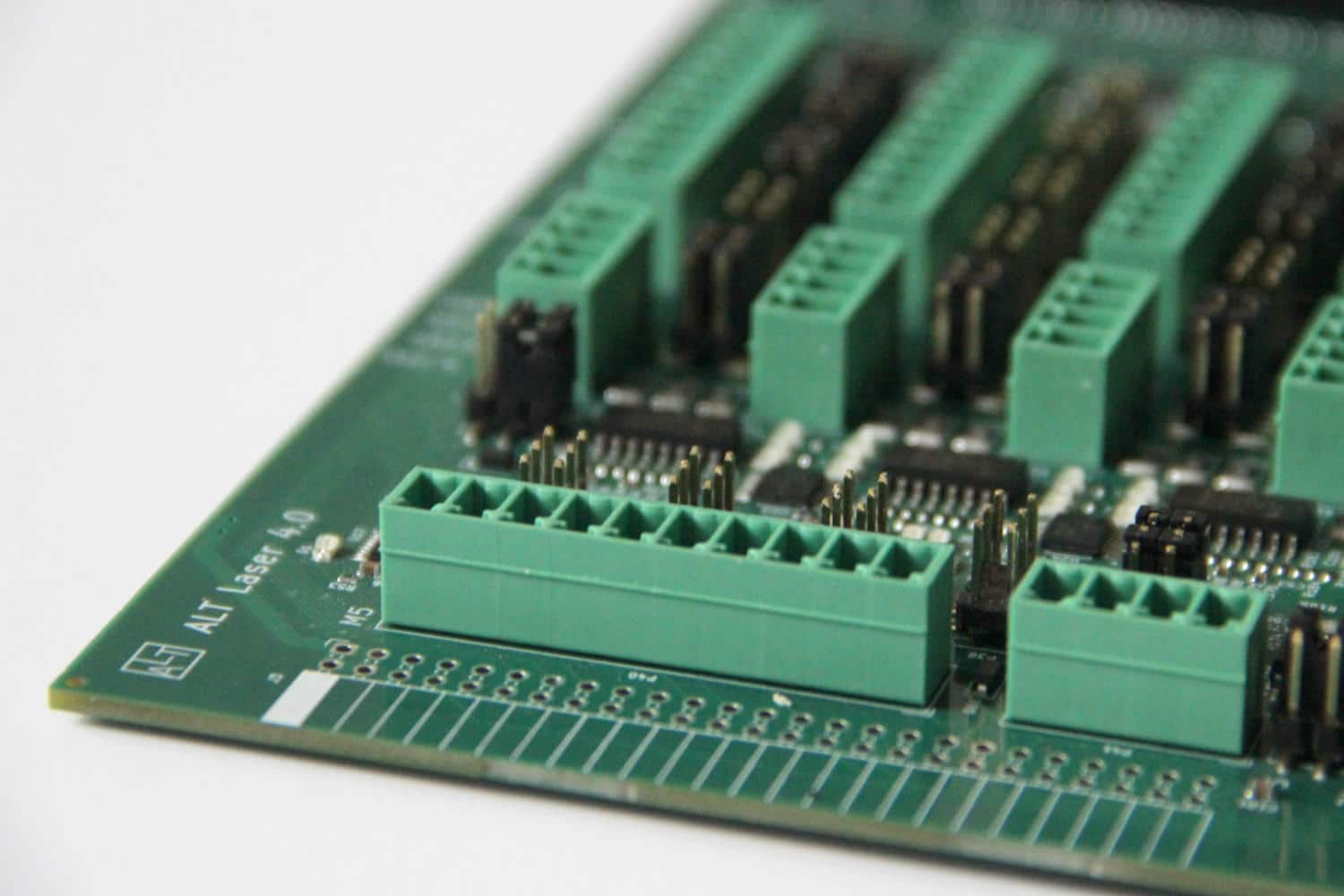

Electronics

All machine functions, laser power regulation, and safety features are managed by electronics. We develop our own hardware, which supports integration of lasers into production lines and automated handling of materials and products. The hardware can be flexibly adapted to meet specific customer needs.

Software

The control software ensures smooth machine operation, safety functions, and optimization of laser output according to current movement speed. Our system, proven over 25 years of operation, is customized for each customer to be as user-friendly as possible. The laser and any peripherals can be controlled from a single application, significantly simplifying operation.